Fermentation technology:

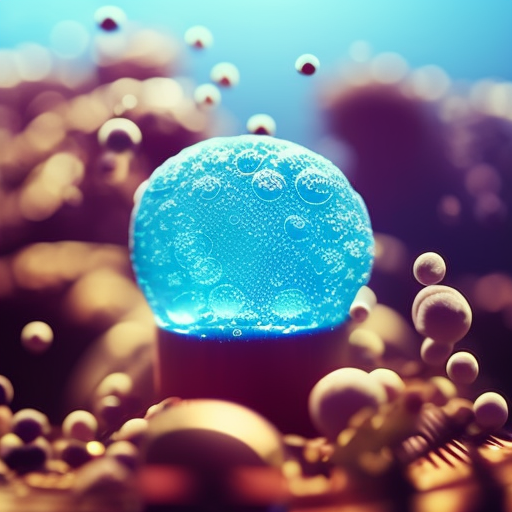

Fermentation technology is a process that uses microorganisms to convert organic compounds into useful products. It has been used for centuries in the production of food and beverages, such as bread, cheese, beer, and wine. In recent years, fermentation technology has gained significant attention in various industries, including pharmaceuticals, biofuels, and bioplastics.

Types of fermentation:

There are several types of fermentation used in different applications. The most common types include:

1. Alcoholic fermentation: This type of fermentation is used to produce alcoholic beverages, such as beer and wine. It involves the conversion of sugars into alcohol and carbon dioxide by yeast or bacteria.

2. Lactic acid fermentation: Lactic acid fermentation is used in the production of dairy products, such as yogurt and cheese. It involves the conversion of sugars into lactic acid by lactic acid bacteria.

3. Acetic acid fermentation: Acetic acid fermentation is used in the production of vinegar. It involves the conversion of ethanol into acetic acid by acetic acid bacteria.

4. Butyric acid fermentation: Butyric acid fermentation is used in the production of butyric acid, which is used as a flavoring agent and in the production of pharmaceuticals.

Applications of fermentation technology:

Fermentation technology has a wide range of applications in various industries. Some of the key applications include:

1. Food and beverage industry: Fermentation is widely used in the production of food and beverages. It is used to produce bread, cheese, yogurt, beer, wine, and many other products. Fermentation helps in improving the taste, texture, and nutritional value of these products.

2. Pharmaceutical industry: Fermentation technology plays a crucial role in the production of pharmaceuticals. It is used to produce antibiotics, vaccines, enzymes, and other therapeutic proteins. Fermentation allows for the large-scale production of these products in a cost-effective and efficient manner.

3. Biofuel production: Fermentation technology is used in the production of biofuels, such as ethanol and butanol. It involves the fermentation of sugars derived from biomass, such as corn, sugarcane, and cellulosic materials. Fermentation provides an alternative to fossil fuels and helps in reducing greenhouse gas emissions.

4. Bioplastics production: Fermentation technology is used in the production of bioplastics, which are biodegradable and derived from renewable sources. It involves the fermentation of sugars derived from plants, such as corn and sugarcane, to produce polymers that can be used as an alternative to conventional plastics.

Advantages of fermentation technology:

Fermentation technology offers several advantages over traditional chemical processes. Some of the key advantages include:

1. Environmentally friendly: Fermentation processes are often more environmentally friendly than traditional chemical processes. They produce fewer harmful byproducts and reduce the reliance on fossil fuels.

2. Cost-effective: Fermentation processes can be cost-effective, especially for large-scale production. They require less energy and raw materials compared to traditional chemical processes.

3. High product yield: Fermentation processes can achieve high product yields, resulting in higher productivity and profitability.

4. Flexibility: Fermentation processes are highly flexible and can be easily optimized for different products and applications. They can be scaled up or down based on production requirements.

In conclusion, fermentation technology is a versatile and widely used process that has numerous applications in various industries. It offers several advantages, including environmental sustainability, cost-effectiveness, high product yield, and flexibility. With ongoing advancements in biotechnology and genetic engineering, fermentation technology is expected to play an even more significant role in the production of valuable products in the future.