Tissue Engineering: Creating Functional Tissues and Organs

Tissue engineering is a multidisciplinary field that combines biology, engineering, and medicine to create functional tissues and organs. It aims to repair or replace damaged or diseased tissues by using a combination of cells, biomaterials, and biochemical factors. This innovative approach has the potential to revolutionize healthcare by providing new treatment options for a wide range of conditions.

The Three Key Components of Tissue Engineering

Tissue engineering involves three key components: cells, scaffolds, and biochemical factors.

Cells: Cells are the building blocks of tissues and organs. In tissue engineering, cells can be obtained from various sources, including the patient’s own body (autologous cells), donated tissues (allogeneic cells), or even stem cells. These cells are then cultured and expanded in the laboratory before being seeded onto scaffolds.

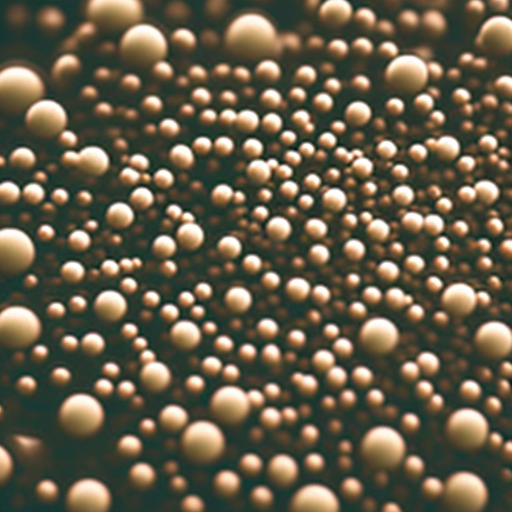

Scaffolds: Scaffolds provide a three-dimensional structure for the cells to grow and organize into functional tissues. They are typically made from biocompatible materials, such as polymers or decellularized tissues. The scaffold acts as a temporary support system, guiding the cells’ growth and providing mechanical stability until the tissue is fully formed.

Biochemical Factors: Biochemical factors, such as growth factors and cytokines, play a crucial role in tissue development and regeneration. They can be added to the culture medium or incorporated into the scaffold to promote cell proliferation, differentiation, and tissue formation. These factors help mimic the natural environment and guide the cells towards the desired tissue type.

The Tissue Engineering Process

The tissue engineering process involves several steps, including cell isolation and expansion, scaffold fabrication, and tissue maturation.

Cell Isolation and Expansion: Cells are isolated from the patient or a donor and cultured in the laboratory. They are then expanded to obtain a sufficient number of cells for tissue engineering applications. This step requires careful control of cell growth conditions, such as temperature, nutrient supply, and oxygen levels.

Scaffold Fabrication: Scaffolds can be fabricated using various techniques, including 3D printing, electrospinning, and decellularization of natural tissues. The choice of scaffold material and fabrication method depends on the specific tissue being engineered. The scaffold should have the appropriate mechanical properties, porosity, and surface characteristics to support cell attachment, proliferation, and tissue formation.

Tissue Maturation: After seeding the cells onto the scaffold, the tissue construct is placed in a bioreactor or incubator that provides the necessary conditions for tissue maturation. This includes maintaining appropriate temperature, oxygen levels, nutrient supply, and mechanical stimulation. Over time, the cells proliferate, differentiate, and organize into functional tissues that closely resemble their natural counterparts.

Applications and Challenges

Tissue engineering has the potential to revolutionize healthcare by providing new treatment options for a wide range of conditions, including organ failure, tissue damage, and congenital abnormalities. It offers the possibility of creating patient-specific tissues and organs, reducing the risk of rejection and the need for immunosuppressive drugs.

However, there are several challenges that need to be addressed for tissue engineering to become a widespread clinical reality. These include:

- Vascularization: Creating a functional blood supply is crucial for the survival and integration of engineered tissues. Researchers are exploring various strategies, such as incorporating blood vessel-like structures into the scaffolds or using bioactive molecules to promote blood vessel formation.

- Immunological Response: The immune system can recognize and reject the engineered tissues as foreign. Strategies to overcome this challenge include using immunomodulatory biomaterials or encapsulating the cells within a protective barrier.

- Scale-up and Manufacturing: Scaling up tissue engineering processes to produce tissues and organs on a larger scale is a significant challenge. Researchers are exploring automated manufacturing techniques and bioreactor systems to overcome this hurdle.

- Regulatory Approval: Tissue engineering products need to undergo rigorous testing and regulatory approval before they can be used in clinical settings. This process ensures their safety, efficacy, and quality.

Despite these challenges, tissue engineering holds great promise for the future of regenerative medicine. Continued research and technological advancements will help overcome these hurdles and bring tissue-engineered therapies to patients in need.