Nanocomposites: A Comprehensive Overview

Nanocomposites are materials that combine nanoparticles with a matrix material to create a new material with enhanced properties. These materials have gained significant attention in recent years due to their unique characteristics and potential applications in various fields, including electronics, medicine, and aerospace.

Definition and Composition

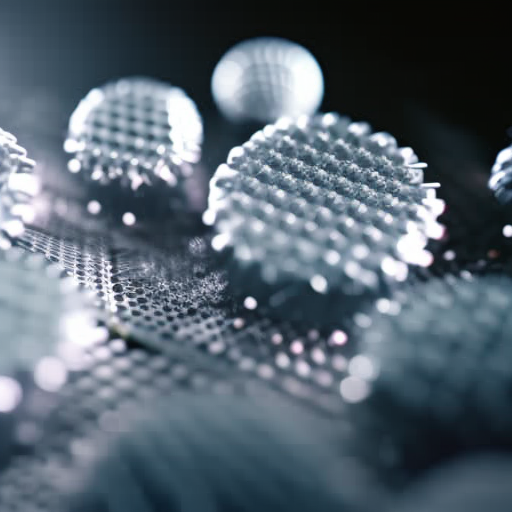

Nanocomposites are typically composed of two main components: nanoparticles and a matrix material. The nanoparticles can be metallic, ceramic, or polymeric, while the matrix material is usually a polymer or a metal. The nanoparticles are dispersed throughout the matrix material at the nanoscale level, resulting in a material with improved properties.

Enhanced Properties

The incorporation of nanoparticles into a matrix material can lead to several enhanced properties. One of the most significant advantages is increased mechanical strength. The presence of nanoparticles can reinforce the matrix material, making it more resistant to deformation and improving its overall strength. Nanocomposites also exhibit improved thermal stability, electrical conductivity, and barrier properties. These enhanced properties make nanocomposites attractive for a wide range of applications.

Preparation Methods

There are several methods for preparing nanocomposites, including solution mixing, melt blending, and in-situ polymerization. Solution mixing involves dispersing nanoparticles in a solvent and then mixing them with the matrix material. Melt blending, on the other hand, involves melting the matrix material and then adding the nanoparticles. In-situ polymerization involves the simultaneous formation of the polymer matrix and the nanoparticles. Each method has its advantages and disadvantages, and the choice of method depends on the desired properties of the nanocomposite.

Applications

Nanocomposites have found applications in various fields. In the electronics industry, nanocomposites are used to develop high-performance materials for electronic devices. For example, nanocomposites with enhanced electrical conductivity are used in the production of conductive films and coatings. In the aerospace industry, nanocomposites are used to develop lightweight materials with improved mechanical properties, such as strength and toughness. Nanocomposites are also being explored for medical applications, such as drug delivery systems and tissue engineering scaffolds.

Challenges and Future Directions

Despite the numerous advantages of nanocomposites, there are still challenges that need to be addressed. One of the main challenges is achieving a uniform dispersion of nanoparticles within the matrix material. Agglomeration of nanoparticles can lead to a decrease in the desired properties of the nanocomposite. Another challenge is the scalability of the production process. While laboratory-scale production methods have been developed, scaling up the production of nanocomposites remains a challenge.

In the future, research efforts will focus on addressing these challenges and exploring new applications for nanocomposites. Scientists and engineers will continue to develop new methods for the synthesis and characterization of nanocomposites. Additionally, efforts will be made to optimize the properties of nanocomposites for specific applications. With ongoing advancements in nanotechnology, nanocomposites are expected to play a significant role in various industries in the coming years.

Conclusion

Nanocomposites are materials that combine nanoparticles with a matrix material to create a new material with enhanced properties. These materials have a wide range of applications and offer improved mechanical strength, thermal stability, electrical conductivity, and barrier properties. Various methods can be used to prepare nanocomposites, and ongoing research aims to address challenges and explore new applications. With their unique characteristics, nanocomposites are expected to have a significant impact on various industries in the future.