Summary:

Flexible electronics is a rapidly advancing field that involves the development of electronic devices and circuits that can be bent, twisted, and stretched without losing functionality. These flexible devices have the potential to revolutionize various industries, including healthcare, consumer electronics, and energy.

Introduction:

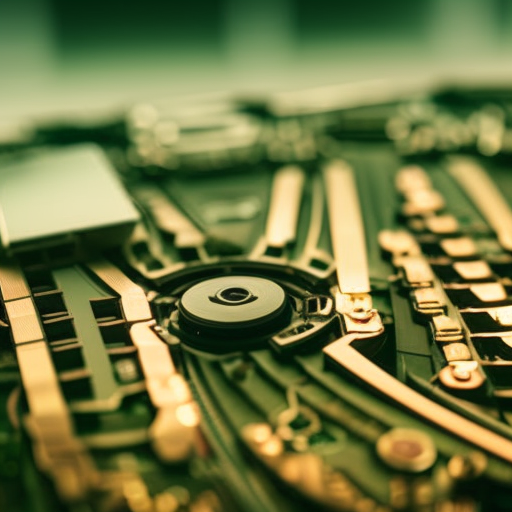

Flexible electronics, also known as flex circuits or flex boards, refer to electronic circuits that can be bent, folded, or twisted without breaking or losing functionality. This emerging technology has gained significant attention due to its potential to enable a wide range of applications that were previously impossible with rigid electronics. Flexible electronics are made using flexible substrates, such as plastic or metal foils, which allow for the creation of lightweight, thin, and flexible devices.

Advantages and Applications:

The advantages of flexible electronics are numerous. Firstly, they offer improved mechanical durability, as they can withstand bending and stretching without damage. This makes them ideal for wearable devices, such as smartwatches and fitness trackers, which need to conform to the shape of the human body. Secondly, flexible electronics are lightweight and portable, making them suitable for applications where weight and size are critical factors, such as aerospace and military technologies. Additionally, flexible electronics can be produced using low-cost manufacturing techniques, such as roll-to-roll printing, which makes them more affordable compared to traditional rigid electronics.

The applications of flexible electronics are vast and diverse. In the healthcare industry, flexible sensors can be used to monitor vital signs, such as heart rate and blood pressure, in real-time. These sensors can be integrated into wearable devices or even directly onto the skin, providing continuous monitoring without discomfort. Flexible electronics also have the potential to revolutionize the field of prosthetics by creating flexible and lightweight artificial limbs that mimic the natural movement of human limbs.

In the consumer electronics sector, flexible displays are a promising application of this technology. Flexible OLED (organic light-emitting diode) displays can be rolled up or bent, enabling the development of flexible smartphones, tablets, and e-readers. These devices offer enhanced portability and durability compared to their rigid counterparts. Flexible electronics also have potential applications in the energy sector, where they can be used to create flexible solar panels that can be integrated into various surfaces, such as buildings and vehicles, to generate clean and renewable energy.

Challenges and Future Outlook:

Despite the numerous advantages and potential applications, there are still challenges that need to be overcome for flexible electronics to become mainstream. One of the major challenges is the development of reliable and robust manufacturing processes that can produce flexible devices at a large scale and low cost. Additionally, ensuring the long-term reliability and stability of flexible devices in harsh environments, such as extreme temperatures and humidity, is another area of concern.

However, researchers and engineers are actively working on addressing these challenges. Advances in materials science, such as the development of flexible and stretchable materials, are paving the way for the production of more reliable and durable flexible electronics. Furthermore, advancements in manufacturing techniques, such as 3D printing and roll-to-roll processing, are making it easier to produce flexible devices in large quantities.

In conclusion, flexible electronics hold great promise for the future of technology. Their ability to bend, twist, and stretch opens up a wide range of possibilities for applications in healthcare, consumer electronics, energy, and more. While there are still challenges to overcome, ongoing research and development efforts are steadily pushing the boundaries of what is possible with flexible electronics.